Introduction to Ceramic Matrix Composites (CMCs)

The Significance of CMCs in Modern Engineering

Ceramic Matrix Composites (CMCs) have emerged as a cornerstone in advanced composite materials, renowned for their resilience in the face of extreme conditions. By amalgamating the robustness of ceramics with the adaptability of composites, CMCs stand as a testament to innovation, offering unmatched resistance to heat, wear, and corrosion. This section illuminates the pivotal role of CMCs in contemporary engineering, paving the way for a comprehensive exploration of their characteristics, benefits, and applications.

Core Composition of CMCs

At their core, CMCs are engineered from ceramic fibers meticulously woven into a ceramic matrix. This distinctive composition preserves the intrinsic advantages of ceramics, such as their ability to withstand high temperatures and their notable hardness, while simultaneously addressing their primary limitation—brittleness. As a result, CMCs exhibit exceptional durability and can endure significant mechanical stress, showcasing their suitability for critical applications where performance under extreme conditions is crucial.

Types and Properties of Ceramic Matrix Composites

Exploring the Diversity of CMCs

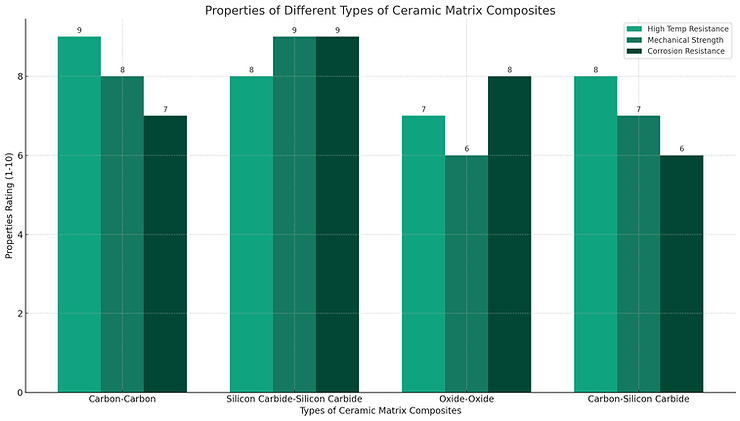

The world of CMCs is diverse, with classifications based on the materials used for fibers and matrices. This section delves into various types of CMCs, such as Carbon-Carbon, Silicon Carbide-Silicon Carbide, and Oxide-Oxide Composites, highlighting their unique applications from aerospace to chemical processing due to their specialized properties like thermal shock resistance and corrosion resistance.

Advantages of CMCs Over Traditional Materials

CMCs stand out for their remarkable performance under conditions that would compromise most metals and polymers. Their ability to maintain structural integrity at temperatures above 1000°C is unparalleled, making them indispensable in sectors like aerospace and automotive. This section examines the high-temperature stability, corrosion resistance, and other properties that contribute to the long-term value and reliability of CMCs.

Manufacturing Techniques of Ceramic Matrix Composites

Innovations in CMC Production

The production of CMCs involves advanced methods to integrate ceramic fibers within a ceramic matrix. Techniques such as Powder Dispersion, Polymer Impregnation and Pyrolysis (PIP), and Chemical Vapor Infiltration (CVI) are meticulously detailed, showcasing how each process is tailored to achieve the desired properties of the composite.

Industrial Applications and Future Perspectives of CMCs

CMCs in Action: From Aerospace to Energy

CMCs have been adopted across a broad spectrum of industries, finding use in aerospace engines, automotive brake systems, and even nuclear reactor components. This section illustrates the widespread applications of CMCs, emphasizing their role in enhancing performance and efficiency in various fields.

The Road Ahead for CMC Technology

Looking forward, the section discusses ongoing research aimed at augmenting the toughness and durability of CMCs, exploring potential uses in emerging sectors like renewable energy and biomedical devices. The evolution of manufacturing technologies and material science is poised to broaden the accessibility and applicability of CMCs, marking a new era in engineering and manufacturing.

Properties of Different Types of CMC’s

Choosing the Right Ceramic Matrix Composite

Navigating the Selection Process

Selecting an appropriate CMC requires a careful evaluation of the operational environment, desired material properties, and budget considerations. This conclusive section offers guidance on balancing factors such as temperature tolerance, mechanical stress resilience, and corrosion exposure against the performance characteristics and production costs of CMCs.

Conclusion: Revolutionizing Industries with Ceramic Matrix Composites

Ceramic Matrix Composites represent a leap forward in material technology, addressing some of the most stringent engineering challenges. With continuous advancements in research and production techniques, the scope of CMC applications is set to expand, promising to redefine industries that depend on materials capable of withstanding extreme conditions.

Our Services

At Corvus Composites, we are at the forefront of advanced composite manufacturing, specializing in Ceramic Matrix Composites (CMCs). Leveraging cutting-edge technologies and innovative engineering solutions, we offer tailored support for your specific requirements. Whether you’re exploring the benefits of CMCs for aero-engine applications or seeking to harness their exceptional properties for high-temperature environments, our team is equipped to guide you through every step of the process. With our expertise, we can help you unlock the full potential of CMCs to meet your engineering and design challenges. Connect with us to discover how we can assist in advancing your projects with the latest in composite material solutions.