To decrease environmental consequences and fulfill demand, recycling fiber-reinforced advanced composite manufacturer will play a significant role in the future, particularly for wind energy, aerospace, automotive, construction, and marine industries.

Fiber-reinforced plastic composite materials are becoming more used in a variety of sectors. This widespread usage has resulted in a massive rise in trash generation, which must be handled without severe environmental difficulties. Recycling fiber-reinforced plastic composite materials in line with circular economy concepts might be one solution to these issues. As a result, this article aims to conduct an empirical analysis of the available scientific literature on recycling systems for fiber-reinforced plastic composite materials.

The primary purpose is to give a complete and holistic overview of the issue, research gaps, and future directions using a rigorous and transparent manner. More than 150 papers were chosen using a systematic methodology and then analyzed using bibliometric analysis. The findings reveal that this area has gained traction recently, with researchers conducting experimental experiments on chemical and thermal recycling strategies for recovering carbon fibers. Finally, this article offers an in-depth research agenda based on identified research gaps and an improved management understanding of this study area.

Recycling Methods

Because of the ongoing use of limited resources and the necessity to handle waste management, there has been increasing concern for the environment, resulting in enhanced material recycling.

Because polymers are often more challenging to recycle and the recycling process is also costly, landfilling has proved a very cost-effective means of disposing garbage based on polymer composites in many circumstances. Carbon fiber manufacturer often generate up to 40% scrap material, which might end up in landfills or garbage incineration.

Policies encouraging recycling have been implemented in addition to using economic mechanisms such as levies to conserve the environment.

What can we do to decrease composite waste?

Waste management has grown in significance in the European Union. To minimize it, trash avoidance should begin at the manufacturing stage by reusing a product, recycled material, waste incineration, and landfill reduction. In contrast to quick-melting thermoplastics, thermoset composites have a cross-linked structure and cannot be created. Several thermoset polymers, including polyurethane, may be readily converted back to their original monomer.

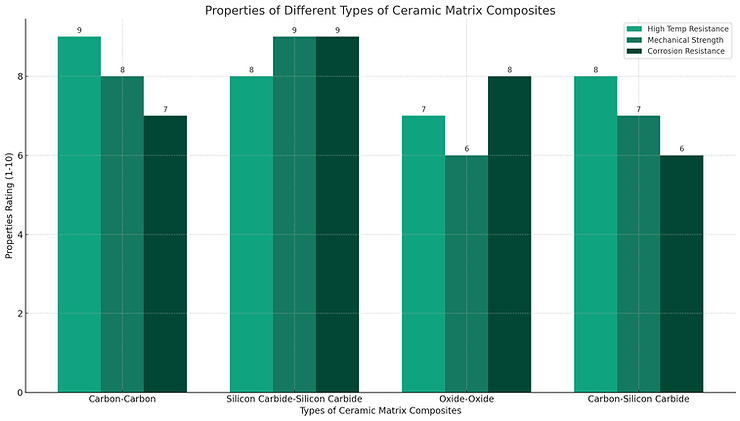

Commercially available thermosetting resins, on the other hand, such as polyester and epoxy resin, are challenging to depolymerize back into their starting monomers. At this time, it may be expected that complete fiber recovery, often known as a direct structural recycling technique, would assist the composite manufacturer. Because of the minimal use of natural resources, energy, and labor, as well as the near-virgin fiber quality, recycled fibers from this technology have an added market value. In terms of the breakdown of recycling methods used in research and industry, solvolysis (24%), pyrolysis (31%), and mechanical grinding (18%) have the most acceptability. 20% are referred to as “other” technologies. Several approaches have been tested and validated. These include mechanical, thermal, and chemical-based recycling technologies, with the method chosen depending on the kind of material to be recycled and the application in which it is reused.

What are the challenges of composite recycling?

Furthermore, determining a standard recycling procedure among the many approaches is problematic. For thermoset composites, many recycling techniques have been documented and encouraged. So far, three types of categorization procedures have been reported: mechanical, chemical, and thermal recycling. Mechanical recycling is shredding garbage into recyclates using automated shredding machines. Thermal recycling uses thermal methods to break down waste material for material and energy, while chemical recycling uses reactive media to dissolve the matrix from the fibers.

TRL (Technological Readiness Level) is a framework used in various sectors to measure technology maturity from ideation (basic ideas) through commercialization. Incineration and landfilling are classified as TRL 9, indicating that they are presently operational systems. The average values for pyrolysis for carbon fibers and mechanical milling for glass fiber applications were 8.3 and 8.2, respectively, with a median of 8, putting them at TRL 8.

The conventional pyrolysis of recycled carbon fiber technology is commercially accessible on an industrial scale. Pyrolysis for glass fibers had a mean of 6.25, while mechanical grinding for carbon fibers had a mean of 6.3, with a median of 7. The mean values for fluidized bed pyrolysis and solvolysis were 4.2 and 2.24, respectively. The average value for microwave heating was 3.2.

Recycling’s Impact on Composite Manufacturer, Regeneration, and Future Applications

Lightweight structures allow for lower fuel usage and related air and vehicle traffic emissions. It has been shown that a 10% decrease in a vehicle’s structural weight may result in a 6-8% reduction in fuel consumption.

Recyclability is especially significant for the automobile sector, which is subject to the ELV Directive (2000/53/EC), which requires at least 95% of a new vehicle’s average weight at the end of its life (EoL) to be recycled by January 2015. As a result, material recycling is projected to get increased attention for research initiatives and government funding as a potential strategy for improving the circular economy and sustainability. Most carbon fiber reinforced plastic (CFRP) products are long-lasting and are still in the early stages of their product life cycle.

Why should we apply design standards for composite recycling?

The fiber reinforcement and matrix of advanced composite manufacturer influence the optimal recycling process. If particular items become established on the market, it will be critical to understand how manufacturing leftovers may be recycled and what occurs after the product’s life cycle. Furthermore, standardized design standards and effective end-to-end predictive modeling methodologies are absent for composites and components. The recycling regulations that must be incorporated throughout the design process are currently being formalized.

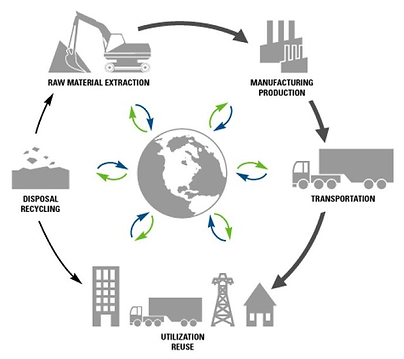

Here we present the essential parts that comprise the skeleton of a product’s end-of-life. Each step has its own set of restrictions and limitations that must be considered. Different stakeholders in the cycle must be evaluated to determine the information that is accessible or required, as well as who acquires or needs it. The anticipated data and decision criteria utilized to transition from one phase to the next should be examined. It is vital to remember that the difference in time between the actual recycling process and the design phase of the components complicates integration.

Constraints and material reuse are well-established for existing and resilient end-of-life approaches. Robust validation for novel recycling processes may take time, but designers must make judgments. Recycling research and development relies on technical breakthroughs to guide future advances. Innovation is required in the recycling phase and all critical stages. Improving disassembly processes or selection efficiency is vital. After the process, it is essential to find novel and practical applications to compete with new raw materials with comparable qualities.

In the case of composites, innovative technologies enable the recovery of fibers with minimal distortion and breakage compared to the original composite component’s original reinforcement. Supercritical fluids may carry the promise of such possibilities in this area. However, the issue of recycled fiber de-alignment and re-alignment persists. Recycling has merged the competencies and abilities required to spin and weave textiles. Another option is to reprocess medium-sized flat rectangular portions of 1D pseudo-unidirectional or 2D woven recovered carbon fiber manufacturer.

The innovation is to suggest a method for building pieces. Specific studies are required to identify the mechanical properties and an efficient material characterization strategy from recycled fibers to the final product according to the product design development phase, including design material constraints and a life cycle analysis (LCA) of RFC in CFRP with different environmental and financial impact categories. This pyramidal testing challenge must include uncertainty at all phases of the product life cycle and all sizes but in real-world tests.

Environmental Context

What are the environmental impacts of composite materials?

The substantial environmental impact caused by human activities and unregulated exploitation of natural resources. Examples of such operations may be found throughout a product’s life cycle, from raw material extraction through product production to trash disposal. Emissions from truck traffic include carbon dioxide, CO2, and particulates, which contribute to global warming and the deterioration of human health. Increasing resource usage as oil depletes nonrenewable resources. Climate change and higher mortality are two of the impacts listed. The increased oil use may result in a shortage owing to inadequate supplies.

Because of this exploitation, the developed world enjoys a high level of life. With this high standard comes a high consumption of items, which leads to a rise in resource and energy usage. The State of the World 2004 report highlights this issue (Worldwatch Institute, 2004). Private consumption has risen fourfold since 1960. The western world, which accounts for 12% of the world’s population, accounts for 60% of this consumption. Consumption in the third world is increasing quickly due to globalization, creating even greater demand for the world’s natural resources. Transportation accounts for 95% of worldwide oil consumption, contributing to one of the world’s most serious environmental issues, global warming, resulting in climate change. Report also recommends that current mechanisms like taxes, laws, durability criteria, and personal responsibility might be used to address unsustainable consumption. “In the long term, satisfying fundamental human needs, increasing human health, and sustaining a natural environment that can sustain us will demand that we regulate consumption, rather than allowing consumers to rule us,” concludes the book (Worldwatch Institute, 2004).

How are we going to get rid of composite material waste?

Waste output is growing in tandem with rising demand. The European Union’s (EU) garbage production grew by 10% between 1990 and 1995. In 1995, garbage was 1,3 billion tons (excluding agricultural waste) (EEA, 1999a). In the same research, a prediction for 2010 revealed that trash would continue to grow. For example, the number of discarded automobiles will rise by 35% between 1995 and 2010.

A landfill is a final resort when all other options have been exhausted. Several techniques, including taxes and laws, have been developed to encourage material recycling (SFS, 1998a). Some examples are legislation to assure producer responsibility for packaging material, paper, end-of-life vehicles, and electrical and electronic waste.

What do we define as composite material?

The term composite refers to a mixture of at least two distinct materials. The polymer matrix and fiber are the two essential components. A composite material as a structural idea has existed for a long time in the forms of straw-brick, paper, and reinforced concrete. However, it has existed as a natural substance from virtually the beginning of time, for example, in the form of wood and bone. However, the polymer composites given here are part of a relatively recent class of industrial composites used for roughly a half-century.

What are the differences of composite materials?

What distinguishes composites is that the structural material is created simultaneously with the product. Unique features are specifically produced for the individual product by mixing the two components, fiber, and matrix. The reinforcement, the fibers, which may be inserted randomly or orientated in both continuous and discontinuous forms, provide strength and stiffness. The matrix between the fibers is intended to completely encircle and bind the fibers to transmit load and protect them from external influences.

What does differ composite material quality?

The contact between the fiber and the matrix is critical to the composite’s qualities. Depending on the kind of fiber, multiple ways are used to promote adhesion; application of a coupling agent or oxidation of the fiber surface are two popular approaches. Glass, carbon, and aramid are examples of commonly used fibers. Natural fibers are gaining popularity since they are made from sustainable resources. Polymer composites are classified into two types based on the matrix material: thermoplastic and thermoset. Disparities in chemical structure explain the differences between these two groupings.

During the curing process of thermosets, a three-dimensional network of cross-linked polymer chains is created. This procedure is irreversible, so heating does not soften the substance. On the contrary, when thermoplastics are heated, they soften because no chemical reaction occurs. Polypropylenes, polyamides, and polyketones are the most often used thermoplastic matrices for composites. Unsaturated polyester, vinyl ester, epoxy, and phenolics are popular thermoset matrices.

Other compounds are mixed in with the mentioned component ingredients. These additives are intended to enhance the composite material’s chemical processes and ultimate qualities. Several additives, such as monomer (curing agent), initiator, and accelerator, are employed in the chemical curing process. Styrene is the most often used curing agent for unsaturated polyester. Fillers, which impact mechanical qualities; flame retardants, which improve fire resistance; and pigments, which provide color, are examples of non-curing additives.

How should we plan composite recycling for the future?

In terms of modeling, the industry requires mathematical models that illustrate the effect of processing parameter variation on recycle quality for all recycling procedures and composite recycling processing parameters on cost and environmental impact projection. Financial and environmental impact are critical factors in ensuring sustainable growth since recycling solutions must be both technically and cost-efficient. Researchers must create mathematical models for these recycling systems to better understand and improve them.

The composite manufacturer future growth is “green” and cheerful, but it strongly relies upon quickly increasing recycling technology and applying Circular Economy (CE) and sustainable thinking.