What are fiber metal laminates?

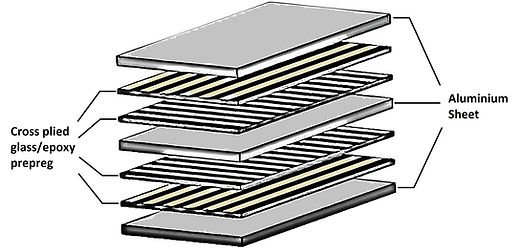

Fiber Metal Laminates, also known as FMLs, are composite materials of thin sheets of high-strength aluminum alloy that are alternatively attached to plies of fiber-reinforced epoxy resin. FMLs provide significant weight reductions compared to the metallic structures already in use. Compensating the increased cost of the materials now available in certain cases. These characteristics, along with exceptional fatigue resistance, provide material damage-tolerant qualities. There was a new approach to this hybrid material, referred to as fiber-metal laminates with a splice or spliced laminates. This approach led us also to use larger laminates to enrich the large dimensions in manufacturing.

How did we start using FMLs?

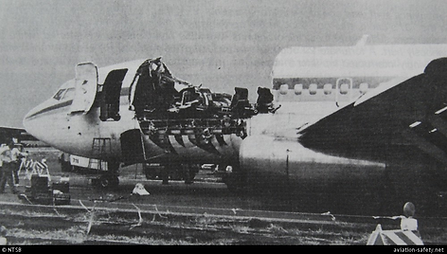

Fracture Mechanics is a developing continuously. This new developments leads new design methodology called Damage Tolerance. Using this technique it is aimed to provide controlled parts with increased damage tolerances. To main purpose was to avoid accidents like Aloha Aircraft Accident(Picture 1).

United State Air Force was leading this new methodology and concept and published in 1974. Additionally, the FAA also supported this with FAR 25.571. The European aviation authority also adopted the same methodology and realeased it in JAR 25.571. (Joint Airworthiness Requirements). Our comprehension of the formation of fatigue cracks has significantly expanded.

Nevertheless, knowledge of fatigue fracture formation in aviation materials does not necessarily mean critical conditions would no longer arise. This is because such an implication would be contradicted by the following: Higher loading is most often utilized when trying to minimize the airframe’s weight. When designing airplanes, the total weight of the structure considerably impacts how well the airplane flies. Low structural weight is of utmost importance because the ratio of an aircraft’s maximum payload to its maximum take-off weight measures the aircraft’s efficiency. This ratio is improved when the weight of the aircraft structure is decreased, so having a low structural weight is beneficial. This indicates that the materials must have a high specific strength to be used. Techniques that are more sophisticated and higher-quality materials are required to develop the construction of a contemporary airplane fuselage. Taking into account skin cracks coming from fatigue and selecting materials and stress levels in such a manner that the cracks will be identified within a specified inspection interval before the cracks reach a threshold fracture length that may lead to catastrophic failure is one of the essential parts of building an aircraft fuselage structure; this period corresponds to the fail-safe life. The structure’s behavior regarding the emergence of cracks is the determining element in creating an inspection program. An adequate degree of safety may thus be maintained via an inspection program. The cost-effectiveness of an aircraft currently in operation is negatively impacted when it must undergo inspections and maintenance. During full-scale testing conducted under realistic situations, fatigue key spots may be identified and pinpointed. Regrettably, even though they are rigorously planned, tested, manufactured, and maintained, catastrophic accidents still occur with aircraft operating. Identifying the primary factors that led to such failures is difficult. Reduce the time spent on inspections, resulting in less efficient aircraft use. Create novel materials for airplanes that have improved fatigue resistance, ideally greater specific strength, and reduced density. It has a family of better damage tolerance materials, superior fatigue behavior, and a significant weight-saving potential, and it has received widespread recognition as one of those materials.

Where does FMLs applied?

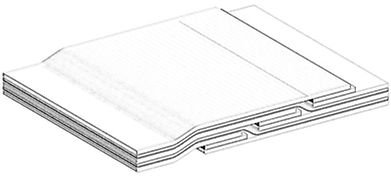

In addition, it can apply the fibers in two different directions, making it suitable for usage in areas subject to biaxial loads, such as fuselages and tailplanes. Spliced Laminates, a revolutionary idea for fibers-metal laminates (ARALL & GLARE), were introduced by the Structural Laminates Company (SLC) in the year 1992. In the long run, these defects will appear in every engineered structure. Some models are accessible that are satisfactory for monolithic materials, and these models are now being applied in practice (Picture 2).

FMLs in aerospace industry

Introducing new materials considerably impacts the design process of a new generation of aircraft. In most cases, acceptance of structural applications by aircraft designers requires a period that spans many decades. Introducing a new material requires the coordinated efforts of several disciplines, and it always begins with the investment of a significant amount of time and money; to put it another way, it is an economically hazardous endeavor. The fuel used and the money spent on maintenance are two of the most important parts of “Direct Operating Costs.” “Ongoing attempts have been undertaken to build airplane structures in novel materials to achieve considerable weight reductions while also reducing the amount of maintenance required.” It was discovered at the Delft University of Technology that the fatigue crack development rates in adhesively bonded sheet materials might be slowed down to a more manageable level. The slowing down of the crack development rates is maintained for as long as possible or until a crack appears in the sheet next to it. The primary motivation behind the research conducted at Delft was pursuing a material that exhibited high resistance to fatigue.

When it comes to lowering production costs while keeping the same level of safety, aircraft manufacturers are continually looking for new replacement options. In recent years, these leading-edge novel alloys have emerged as the most significant advancement in aluminum material. The breakthrough of Al-Li alloys is still up in the air, and the use of these materials in civil aviation is still restricted. In recent years, some incremental progress has been made in the research and production of carbon fiber-reinforced epoxies, sometimes known as “Advanced Composites.” In the 1950s, they were marketed as fatigue-resistant materials that would save between 20 and 30 percent of the total weight. In addition, it was said that their use would result in cheaper manufacture owing to the reduced number of components. However, to accomplish the desired weight reduction while using composite materials, it will be essential to develop new structural design principles. After forty years, significant weight reductions and broad usage of these composite materials for key sections in aircraft constructions are still quite low. This is even though these materials have been available for decades.

Why do we use Aramid-Reinforced Aluminium Laminate (ARALL)?

Materials made of fiber composites satisfy these requirements, except for fracture toughness. The laminates produce a particularly damage-resistant material as a consequence of the fact that two metal layers support every prepreg layer in each laminate. When fatigue fractures appear, the laminates are built in such a way that they prevent the fibers from failing. Compared to other aircraft materials on a structural level, ARALL laminates emerge as promising options, particularly for fatigue-dominated structural elements like the lower wing skin and the pressurized fuselage cabin [9J. A novel hybrid material known as ARALL was created by doing things this way. However, post-stretching will increase manufacturing costs, making it difficult to do on large panels. Although it is feasible to fix issues caused by fiber failure, post-stretching will not. We would want an ARALL that is more isotropic and has fibers running in more than one direction. Recent studies have indicated that Care laminates have fiber failure during flight-simulation fatigue testing at increased stress levels, which results in poor fatigue performance. This failure was caused by the laminates’ inability to withstand the stress. As a direct result of this, it has been seen very seldom that the glass fibers break as a result of the fatigue stress. Because of this, certain structures that experience biaxial stresses are significantly more suited for using this. These characteristics provide the impression that GLARE might be used in a more extensive variety of contexts.

Why Do We Use Glass Reinforced Laminate (GLARE)?

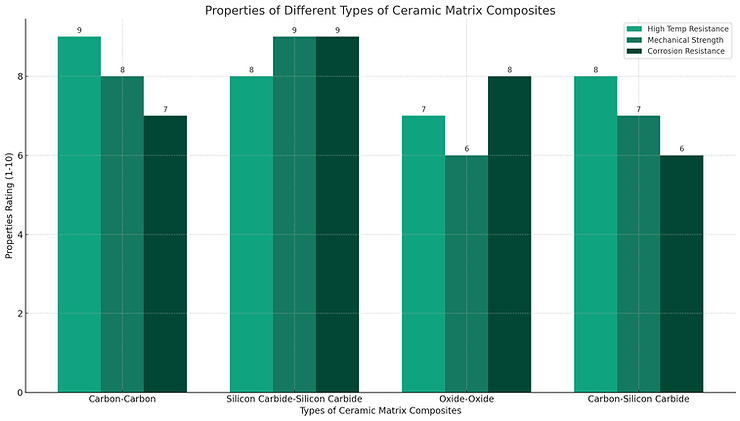

The primary motivation for the Development of the GLARE laminates (Figure 1) was pursuing a material with high fatigue crack growth resistance without experiencing fiber failure, improved notch strength, and fiber lay-up in a biaxial manner. GLARE’s properties make it an outstanding material that is both lightweight and resistant to flame. Within one minute, the situation will have stabilized, and it will remain unchanged for the remainder of the test. Recent flame tests approved GLARE for use in cargo areas successfully carried out. The acceptability of these new materials, on the other hand, will rely, as it always has, not only on the cost balance over the aircraft’s lifetime but also on the Development of new construction methods” to take full use of the qualities of the material. Another trade is known as GLARE “A term used by Akzo for ARALL that contains R-glass fibers. A few of the applications have already been realized, while others are in the process of being fully realized. The vast majority of these components have previously been thought about and looked at by several different manufacturers.

The resistance to wear and damage that GLARE provides results in considerable savings not only in terms of weight but also in terms of cost. There was a 15–25% reduction in weight throughout the Airbus family when GLARE was applied to the fuselage skins. In pressurized fuselages, the riveted joints are subjected to intense fatigue stress in both the circumferential and the longitudinal directions. Because of the harsh and biaxial-load conditions in the fuselage skin, the application as a material for the fuselage skin requires a cross-ply build-up of GLARE 3, which has good fatigue resistance, greater tensile strength, and a lower density in comparison to monolithic aluminum. Because GLARE is a material that is extremely resistant to fatigue and has a reduced specific weight when compared to monolithic aluminum alloy. As a result, replacing aluminum alloys with GLARE is only practicable if significant weight reductions are feasible. The use of GLARE materials in the fuselage skin of wide-body aircraft has been the subject of feasibility studies, which have shown that weight reductions are possible even without modifying the design of the connection between the skin and the frame [14].

In contrast to monolithic aluminum, cross-ply GLARE 3, in particular, has a relatively lower rigidity than monolithic aluminum. This may be the most significant drawback of cross-ply GLARE 3. When utilized as a material for the fuselage skin, GLARE 3 has a lower level of rigidity, which might lead to increased loads in the fuselage frames. For GLARE 3, there will be a reduction in the number of areas that need to use doublers. Because of the same issue, reinforcements are also required where the joints are located.

The cost of manufacturing is a significant consideration for the aircraft designer and the manufacturer. However, the cost of operation is a factor that must be considered when considering the airline industry. Nevertheless, there is now a new alternative for reducing the number of joints and the total number of pieces in a structure. Laminated aluminum sheets are constructed with a fine seam running between each layer. Because the seams in the various aluminum sheets are located in various places, they may be bridged not only by fiber layers but also by the uncut layers of aluminum. The pressurized fuselage, the tension skin of the lower wing, and the tailplanes are all examples of big aircraft components that should give spliced laminates (Figure 2) serious consideration as a potential material choice. Because such charges account for around 35 percent of the whole initial expense of the aircraft, it was discovered that the acceptance of materials is only possible if their behavior in failure mechanisms and the repercussions of the manufacturing procedures used are fully known. To our good fortune, many people who came before us have already done much work.

Conclusion

Recent decades have seen a phenomenal acceleration in the evolutionary process underlying current aeronautical engineering of aircraft design in response to the stringent needs for safety and the competitive cost demands in structural design with new materials. In recent years, safety factors have been reduced significantly. This improves the situation even more. The structure’s weight has always been a key consideration, which is why developing new lightweight materials is essential. When a contemporary, fully loaded, subsonic transport aircraft takes flight, the possibilities, which are only restricted by the technology now available for production, are endless. Stringers have a restricted length since they are rolled from strip stock; however, this length may be expanded by employing spliced laminates. It is reasonable to anticipate that the splices will have an impact on the characteristics of the material. In the current analysis, it has been presumed that the splice site in the GLARE 3 fuselage panel will not be strengthened with doublers in the same manner as the spliced fuselage panel on the Deutsche Aerospace Airbus (DAA) aircraft. Therefore, fatigue is no longer the most important design characteristic, as it is no longer the case for aluminum alloy. When this occurs, it is then feasible to apply high design stresses in aircraft structure components that were previously considered to be fatigue critical. It would seem that the most important design parameter for GLARE right now is the residual strength.

The residual strength of a structure is primarily determined by two aspects: (i) the design characteristics, also known as the structural design idea, and (ii) the fracture toughness qualities of the material. Both of these aspects contribute to the overall design of the structure. The following is a list of the beneficial mechanical qualities provided by FML (ARALL and GLARE).

It also includes:

1. A high strength level results in a higher maximum permitted design stress.

2. A low-density results in a larger potential for weight reduction.

3. Resistance to fire results in increased safety and the need for fewer emergency escape doors.

4. Resistance to fatigue, with fewer opportunities for repair and a longer maintenance period

5. Exceptional workshop qualities, including considerable savings in production costs and the streamlining of production.

6. Excellent resistance to damage and fewer extra components in component constructions, which results in a decrease in weight and savings in manufacturing costs.