Introduction

In the dynamic landscape of automotive design, the quest for lighter, stronger materials has led to a significant paradigm shift. Carbon fiber composites, once reserved for high-performance racing cars and aerospace applications, are now at the forefront of innovation in mainstream automotive design. This article delves into the transformative impact of carbon fiber composites on the automotive industry, exploring their properties, advantages, challenges, and future prospects.

1. Understanding Carbon Fiber Composites

Carbon fiber composites are composite materials comprised of carbon fibers embedded in a polymer matrix, typically epoxy resin. The strength and stiffness of carbon fibers, derived from tightly bonded carbon atoms arranged in a crystalline structure, make them exceptionally lightweight yet incredibly strong. These properties make carbon fiber composites ideal for applications where weight reduction is critical, such as automotive design.

2. Composite Advantages in Automotive Applications

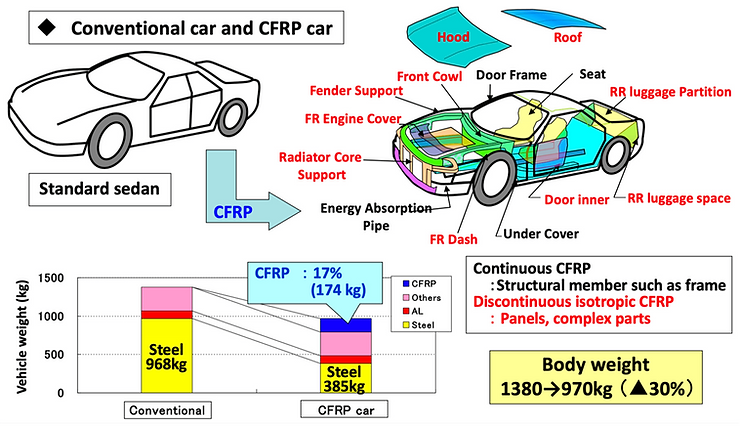

The adoption of carbon fiber composites in automotive design offers a myriad of advantages. Firstly, the lightweight nature of carbon fiber significantly reduces vehicle weight, leading to improved fuel efficiency and lower emissions. Studies have shown that every 10% reduction in vehicle weight can result in a 7% reduction in fuel consumption. Additionally, carbon fiber composites exhibit excellent strength-to-weight ratios, providing enhanced structural integrity and crash protection compared to traditional materials like steel or aluminum.

3. Challenges and Considerations

Despite their numerous benefits, the widespread adoption of carbon fiber composites in automotive design faces several challenges. Chief among these is the cost associated with carbon fiber materials and manufacturing processes. Carbon fibers are more expensive than traditional materials, and the complex manufacturing techniques required to produce carbon fiber components further contribute to the overall cost. Additionally, production time of composite materials is higher compared to traditional materials because of the long resin curing cycle. Finally, concerns regarding the durability and crashworthiness of carbon fiber composites must be addressed to ensure their widespread acceptance in automotive applications.

4. Case Studies: Future Trends and Innovations in Carbon Fiber Automotive Design:

Transition from Supersports to Mainstream Vehicles

As the automotive industry progresses, the transition of carbon fiber from exclusive use in high-performance supercars to integration in mainstream vehicles signifies a significant trend. Let’s explore how this transition has unfolded through three case studies, showcasing the evolution of carbon fiber adoption over the past two decades.

Case Study 1: Ferrari Enzo – Pioneering Carbon Fiber Excellence (20 Years Ago)

The Ferrari Enzo, introduced in the early 2000s, represents a watershed moment in automotive design with its extensive use of carbon fiber. As a limited-production hypercar, the Enzo showcased the potential of carbon fiber in achieving unparalleled performance and aesthetics. From its monocoque chassis to body panels and interior components, carbon fiber played a pivotal role in reducing weight and enhancing structural rigidity, resulting in a supercar that pushed the boundaries of speed and agility.

The Ferrari Enzo set a precedent for carbon fiber adoption in the world of supercars, demonstrating its effectiveness in enhancing performance and establishing a new standard for automotive excellence.

Case Study 2: McLaren MP4-12C – Expanding Carbon Fiber Reach (10 Years Ago)

The McLaren MP4-12C, introduced in the early 2010s, marked a significant step forward in the democratization of carbon fiber technology. As a mid-range sports car, the MP4-12C continued the legacy of its predecessors by incorporating carbon fiber in key structural components while making it more accessible to a broader audience of enthusiasts. The extensive use of carbon fiber in the chassis, body panels, and aerodynamic elements contributed to the MP4-12C’s lightweight construction and exceptional performance, delivering a driving experience previously reserved for supercars.

By expanding the reach of carbon fiber to a wider range of consumers, the McLaren MP4-12C accelerated the transition of lightweight materials from exclusive use in supercars to mainstream sports cars.

Case Study 3: BMW i3 – Carbon Fiber Integration in Everyday Vehicles (Present)

The BMW i3, introduced in the mid-2010s, represents a milestone in the integration of carbon fiber in everyday vehicles. As an all-electric city car, the i3 breaks new ground by incorporating carbon fiber-reinforced plastic (CFRP) in its innovative LifeDrive architecture, which combines a passenger cell made of carbon fiber with an aluminum chassis. This hybrid construction not only reduces weight and enhances safety but also maximizes interior space and driving range, making the i3 a practical and sustainable urban mobility solution.

The BMW i3 showcases how carbon fiber technology has transitioned from the realm of supercars to everyday vehicles, demonstrating its versatility and potential to revolutionize automotive design across all segments.

The transition of carbon fiber from exclusive use in high-performance supercars to integration in mainstream vehicles represents a significant evolution in automotive design. Through case studies such as the Ferrari Enzo, McLaren MP4-12C, and BMW i3, we can observe how carbon fiber technology has progressed over the past two decades, from pioneering excellence to expanding reach and everyday integration.

As automakers continue to innovate and refine carbon fiber manufacturing techniques, we can expect to see further advancements in lightweight materials and their widespread adoption across the automotive industry. From supercars to mainstream vehicles, carbon fiber is poised to reshape the future of mobility, driving advancements in performance, efficiency, and sustainability for years to come.

5. Future Trends and Innovations in Carbon Fiber Automotive Design

As the automotive industry continues to evolve, future trends and innovations in carbon fiber automotive design hold immense potential to shape the vehicles of tomorrow. Let’s explore some key areas where advancements in carbon fiber technology are poised to drive innovation and revolutionize automotive design.

Continuous Advances in Manufacturing Technologies

One of the most significant trends shaping the future of carbon fiber automotive design is the continuous evolution of manufacturing technologies. Traditional methods of carbon fiber production, such as hand layup and vacuum bag forming, are being complemented and, in some cases, replaced by more advanced techniques.

Automated manufacturing processes, such as automated tape laying (ATL) and automated fiber placement (AFP), enable precise control over fiber orientation and resin distribution, resulting in stronger and more uniform components. Furthermore, advancements in resin infusion techniques, autoclave and out-of-autoclave (OOA) curing methods offer greater flexibility and scalability in production, reducing cycle times and manufacturing costs.

These advancements in manufacturing technologies are paving the way for the mass adoption of carbon fiber composites in mainstream vehicles, making lightweight solutions more accessible and cost-effective for automakers.

Integration of Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is another area of innovation that holds tremendous promise for the future of carbon fiber automotive design. By utilizing additive manufacturing techniques, automakers can create complex geometries and custom components with unparalleled precision and efficiency.

Carbon fiber-reinforced polymers (CFRP) can be 3D printed layer by layer, allowing for the creation of lightweight and highly optimized structures that are tailored to specific performance requirements. This approach not only reduces material waste but also enables the integration of functional features, such as cooling channels and load-bearing structures, directly into the component design.

As additive manufacturing technologies continue to mature and become more cost-effective, we can expect to see increased adoption of 3D-printed carbon fiber components in automotive applications, offering greater design freedom and performance optimization possibilities.

Hybridization and Multimaterial Integration

The future of carbon fiber automotive design is not limited to pure carbon fiber components but also involves the integration of multiple materials to achieve optimal performance and functionality. Hybridization, the combination of carbon fiber with other lightweight materials such as aluminum, magnesium, and advanced polymers, offers a synergistic approach to vehicle design.

By strategically integrating different materials based on their specific properties and strengths, automakers can create hybrid structures that maximize strength, stiffness, and energy absorption while minimizing weight and cost. For example, combining carbon fiber with aluminum in a hybrid chassis can offer a balance between rigidity and crashworthiness, resulting in a safer and more efficient vehicle.

Furthermore, advancements in bonding and joining technologies enable the seamless integration of dissimilar materials, allowing for the creation of lightweight and structurally optimized assemblies with superior performance characteristics.

Smart and Functionalized Materials

The future of carbon fiber automotive design also encompasses the development of smart and functionalized materials that offer enhanced performance and functionality. By incorporating sensors, actuators, and other embedded technologies into carbon fiber composites, automakers can create intelligent components that respond dynamically to changing conditions and optimize vehicle performance in real-time.

For example, smart carbon fiber panels with embedded sensors can monitor structural integrity and detect damage or stress concentrations, allowing for proactive maintenance and repair. Similarly, functionalized carbon fiber surfaces with self-healing coatings or adaptive properties can enhance durability and longevity, reducing the need for costly repairs and replacements over the vehicle’s lifespan.

As advancements in materials science and nanotechnology continue to progress, we can expect to see the emergence of innovative carbon fiber composites with enhanced functionality and performance capabilities, further driving the evolution of automotive design towards lighter, stronger, and more intelligent vehicles.

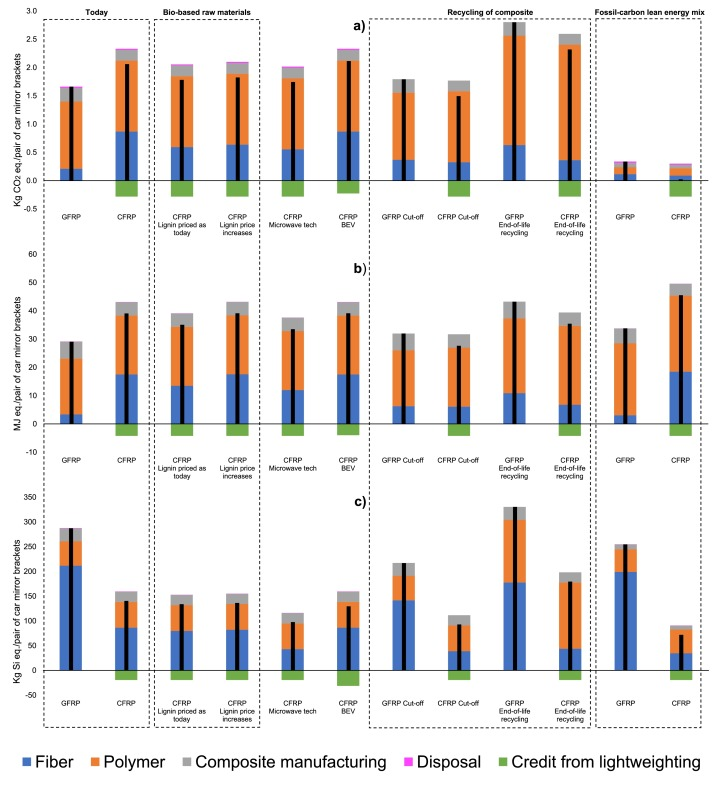

6. Environmental Impact and Sustainability

As the automotive industry shifts towards sustainability, the environmental impact of carbon fiber composites must be carefully considered. While carbon fiber materials offer significant weight reduction benefits, their production process involves energy-intensive manufacturing methods and carbon emissions. Efforts to improve the sustainability of carbon fiber production, such as the development of renewable energy sources and recycling technologies, are essential to mitigate their environmental footprint and ensure a greener future for automotive design.

7. Regulatory and Safety Standards

Regulatory and safety standards play a crucial role in the widespread adoption of carbon fiber composites in automotive applications. Automakers must adhere to stringent safety regulations and testing protocols to ensure the crashworthiness and reliability of carbon fiber components. Furthermore, certifications and quality assurance measures are essential to instill consumer confidence and facilitate market acceptance of carbon fiber technology.

8. Collaborations Driving Innovation

Collaborations between automakers, carbon fiber manufacturers, and research institutions are driving innovation and accelerating the adoption of carbon fiber composites in automotive design. Joint ventures and strategic partnerships enable the sharing of expertise, resources, and technological advancements, fostering a collaborative ecosystem focused on advancing lightweight solutions for future vehicles. Government incentives and funding initiatives further support these collaborations, incentivizing investment in carbon fiber technology and sustainable mobility solutions.

Conclusion

In conclusion, carbon fiber composites are revolutionizing automotive design with their lightweight solutions and unparalleled performance capabilities. From improved fuel efficiency and enhanced safety to innovative applications and sustainability considerations, carbon fiber materials are reshaping the future of mobility. As advancements in manufacturing technologies continue and collaborations drive innovation, the automotive industry is poised for a transformative shift towards lighter, stronger, and more sustainable vehicles powered by carbon fiber composites.