What are Fiberglass Composites?

Any type of material combined together to have greater protperties can be consider composite materials. In this article we try to explain fiberglass composites more in details.

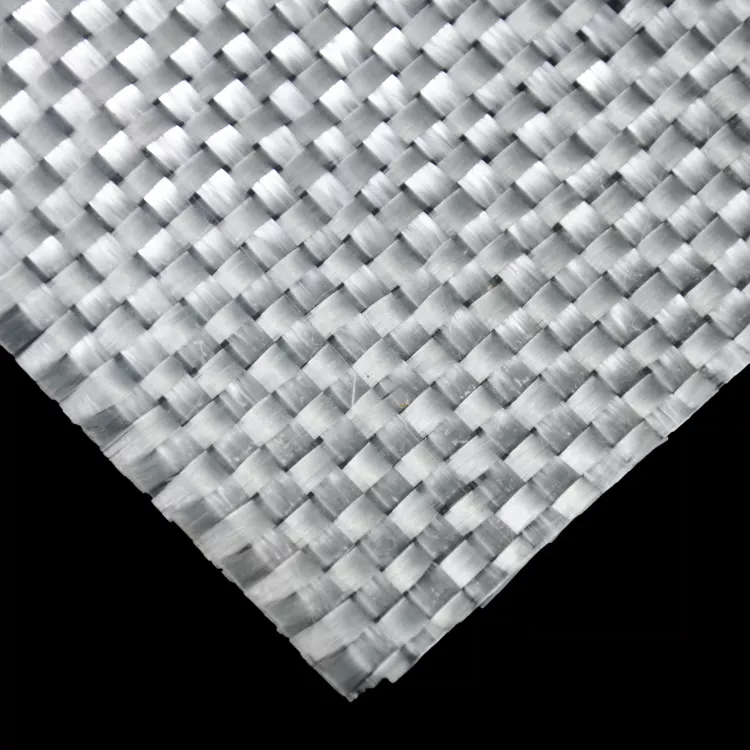

Different GF reinforcements such as long longitudinal, woven mat, chopped fiber, and chopped mat is generated to improve the mechanical and tribological characteristics of the composites. Composite parts are determined by the fibers deposited or laminated in the matrix during composite preparation.

Polyester matrix-based composites have been extensively employed in marine applications; water absorption was a significant characteristic in the degradation of polymer composites in the marine area. Epoxy resins have been extensively used for the applications above because of their excellent chemical/corrosion resistance and minimal shrinkage during curing.

The waste composites are crushed or milled into a finer regrind utilizing mechanical processing processes. The regrind is divided into three recyclate grades. These automatic recycling byproducts may subsequently be employed as filler or reinforcement in new composite manufacturer products, or they can be transported more readily to alternative treatment facilities.

Several variables impacted the energy dissipation of FRP composites, including fiber volume, fiber orientation, matrix material, temperature, moisture, and others such as lamina thickness and composite thickness. The dynamic stability of polymer matrix composites, such as the storage modulus and damping factors, was critical to investigate at low and high temperatures. The composites were exposed to various situations in tribological applications, such as sliding, rubbing, and rolling against other materials or themselves.

Composites have grown in popularity because of their lightweight, superior mechanical qualities and beauty. Approximately 90% of all Fibre-Reinforced Polymers (FRP) are made of glass fibers and a thermoset resin. In 2022, the European manufacturing volume of Glass Fibre Reinforced Polymers was expected to be over 1 megatonne again. Regarding the data we think composites has more potential to provide better material properties than competitors for cheaper costs.

What are the many types and forms of fiberglass, and how are they used?

A fiberglass is a form of fiber-reinforced plastic in which glass fiber serves as the reinforcement. Because of this, fiberglass is also known as glass fiber-reinforced plastic or glass-reinforced plastic. Glass fibers may be made from several kinds of glass. The glass fiber is flattened into a sheet and then randomly placed or woven into a cloth. Fiberglass is lightweight, robust, and less brittle than other materials.

One of the most enticing aspects of fiberglass is its ability to be molded into various forms. This explains why fiberglass is used extensively in building, civil engineering, commercial and residential items, aviation, roofing, and sports equipment. Rene Ferchault de Reaumur, a French scientist, developed glass fiber around the end of the 18th century, but it was mostly ignored. A German glassblower created a piece of fabric by weaving silk strands in one direction and glass fibers in the other.

At the 1893 Chicago World’s Fair, Edward D. Libbey of the Libbey Glass fiber composite Company displayed a garment of such fabric. The outfit broke when folded and weighed 13.5 pounds for demonstrative purposes only. Aside from clothing, glass fibers had the potential for various purposes. However, they were not flexible at the time. These glass fibers could also not be mass-produced.

Fiberglass functions similarly to conventional glass in that it does not absorb moisture:

- It neither molds nor mildews.

- It does not conduct electricity.

- It never rusts, shrinks, expands, or burns.